Like the other industries, leather products need raw materials. However, the main note is that its raw materials are the by-products of the meat industry. Like the many different industries, additives like chemicals accompany the raw materials to make the product. Before telling more about them in detail, there should be a brief explanation of the leather manufacturing process. In a way, the raw materials, including the animal’s skin, accompany the needed chemical changes to the semi-finished products like crust or wet blue. Some of the levels are nearly the same as the other manufacturing entities—the activities like raw material supply, manufacturing, quality control, final or semi-final product, and storage. The manufacturing process includes methods and techniques necessary to make a product. Raw Material supply is always one of the main concerns of the managers. Raw materials always play an essential role in the manufacturer’s balance sheet, which shows assets, debts, and capital. It also plays a vital role in the finished cost product. Generally speaking, raw materials management includes deciding the raw material quality, price, availability, diversity, timing, payment method, and credibility. All manufacturers need a regular system for raw material purchases. A skilled manager in harmony with others should conform with the other sections to prevent waste. A purchase manager should have complete knowledge about technical affairs, be skillful, have the management power to control the department, be familiar with domestic and global markets and ways of supply, and know all details about trade, economy, and legal deals principles.

A brief look at the history of the leather as raw material

The leather industry’s roots lie in history as raw material. However, it has not lost its importance in years and centuries. Leather plays two crucial roles as raw material for many industries and finished products for tanneries, a unique position in manufactured products. Our early fathers tried to use all parts of their hunts to ensure they used them thoroughly. This way of thinking led to the leather industry. They changed the animal skin to leather and used it for many products. Nowadays, we have many different kinds of leather. However, the way is still the same as before with a little bit modernized.

Leather Production Phases from Skin

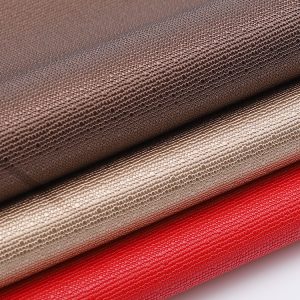

Now let’s look at how raw skin changes to leather as raw material. Most of the skin contains useless parts (like water and hair); removing and preparing them is necessary. After slaughtering, the animal’s skin becomes corrupt soon and can be out of use. So, the water and chemicals rehydrate the skin in the soaking phase to prevent becoming dried and rotted. The unnecessary parts like flesh, protein, and fats are removed in this phase. After rehydrating and eliminating the unneeded parts, it is time to remove hair. The acids and enzymes lower the PH and soften the skin surface. After those steps, the collagen is left, which is a necessary protein, and it is only the critical part of the skin for tanneries. Now is the time for Tanning, which are chemicals turning the skin into leather. The remaining dirt and acids are separated using water in the neutralizing phase, and the PH is raised. The re-tanning with other chemicals is the next level. Depending on the required characteristics of the leather, the needed chemicals kinds determined. The leather is ready to sort out in the withering phase by removing the excess water and chemicals. At this level, according to the quality of the leather, some necessary actions are taken. The leather is shaved if there are still hairs on it. At the Dyeing level, the leather color turns blue by using chromium. At the Fatliqoring level, animal oils are added to the leather to increase its flexibility and softness of the leather. The leather gets dried during the drying process using heating tunnels or vacuum drying. Now it is time to talk about the finishing level. In this step, according to the use of the leather, some special chemicals are used. There are some works done on the appearance of the leather. After this step and the quality final check, the leather is ready to be used as the raw materials for other businesses and industries, like furniture, shoes, bags, apparel, and even luxury products, like cellphone and book covers and Wristwatch-bands.

Leather shoes

In the above and after talking about how to produce leather from Skin, now it is time to look at one of the essential leather products, shoes.

History

Although the early men used leather for many purposes, using it as footwear has been one of the oldest. They used the bear’s and deer’s Skin to cover their feet and protect them through hits, coldness, heat, or other natural elements. Faster running to be away from the danger or chasing the hunts and finally have a better feeling and comfort were the other shoe’s advantages for them. One of the oldest discovered shoes dates back to 5500 years ago in a cave in Armenia. Now, the new and modern human requirements for shoes are almost the same. However, the design and style of the shoes are under the heavy shadow of fashion and technological advances. There are different kinds of leather from other animals, making leather with different qualities making many shoes with additional attributes. The durability and flexibility are the essential characteristics of a shoe.

Types of Leather Shoes

Oxford Shoes: Oxford is an official shoe that was made of ordinary leather before. However, they are available in different colors, designs, and styles. They are adapted initially from Ireland and Scotland, usually worn at formal meetings, though, no problem to use them on informal occasions.

Mank strap shoes: The Mank Strap Shoes originated from Oxford Shoes, with some infrastructural changes and adding straps or buckles, which seems revolutionary. The leather used in these shoes is light.

Derby Shoes: Those shoes are the same as Oxford shoes, but the difference is in their sole and lace. They are available in different kinds and models in the market.

Brouge Shoes : From the appearance, they are very close to the Oxford models, in a way that they consider to be the same in some classifications.

College Shoes: Comfort is their main characteristic, and because of the easy air circulation, they are a suitable choice in summer. Their noiseless heels are another advantage.

Loafer Shoes: The primary qualifications of the loafer shoes are being laceless, short upper, and round up to the ankle. They have two distinct and separate up and down. They are very light, comfortable, and in harmony with different styles and can be worn on formal occasions. The other shoes are boots, including Chelsea, ankle, Chukka, sports shoes, sandals, formal pumps, and high heels (for women).

Conclusion: This article has tried to briefly explain the leather industry as raw materials for the other sectors and how it is produced, its history, and one of the finished products. According to our many years of experience in the leather industry as a supplier for both skins and finished items .

Your comment submitted.